Uncover cutting-edge developments in surface engineering and how material science is shaping the future of technology and industry.

Material science is key to improving surface engineering, leading to new discoveries. These advancements are changing how we work in many fields. From aerospace to medicine, the latest in surface engineering is opening up new possibilities.

This article looks at how material science and surface engineering are connected. We’ll see how these breakthroughs are shaping the future of materials. We’ll also look at recent studies in top journals like “Advances in Materials Research” and “Journal of Material Science.”

Key Takeaways

- Material science is crucial for advancements in surface engineering.

- Innovations in surface engineering technologies enhance industrial applications.

- Recent discoveries significantly impact performance metrics across sectors.

- Publication in reputable journals showcases ongoing research and developments.

- The future of material science is intertwined with surface engineering innovations.

Introduction to Surface Engineering

Surface engineering is key in many industries, making materials better. It changes the surface of materials to get the results we need. This can make them last longer, resist corrosion, or look better.

It’s used in many areas. For example, in making things, it makes parts last longer. In electronics, it helps devices work better. By changing how surfaces look and feel, we make products last longer and work better.

This field keeps getting better thanks to new tech and the need for tough materials. It helps make materials that can handle a lot of use. This means we use resources better and come up with new ideas for designs.

| Surface Treatment Method | Key Benefits | Common Applications |

|---|---|---|

| Coating | Enhanced corrosion resistance | Aerospace, automotive |

| Plasma Treatment | Improved adhesion properties | Electronics, packaging |

| Laser Surface Modification | Increased hardness and wear resistance | Manufacturing, construction |

| Physical Vapor Deposition | Uniform coating and thickness control | Optics, semiconductors |

The Role of Material Science in Technology Advancement

Material science is key to advancing technology. It helps create new materials that improve many tech fields. This is seen in electronics, cars, and space travel.

Polymers and composites are big in this area. Polymers are light and flexible, making gadgets better. Composites are strong and light, making cars safer and more fuel-efficient.

In space, material science makes materials that can handle harsh conditions. This makes planes safer and more efficient.

Studies in Nature Materials show scientists always finding new materials. This keeps material science at the forefront of tech progress. It leads to better, greener solutions in many areas.

Recent Breakthroughs in Surface Engineering

Surface engineering has seen big leaps forward, changing how we work in many fields. New techniques have led to major improvements. These advancements make materials better and last longer.

Innovative Techniques and Methods

At the forefront are laser treatment, thermal spraying, and atomic layer deposition. Each brings its own set of benefits:

- Laser Treatment: Uses high-energy beams to change surface properties, making them harder and more resistant to stress.

- Thermal Spraying: Adds protective layers by melting and spraying material particles, boosting wear resistance.

- Atomic Layer Deposition: Allows for precise control of film thickness, ensuring coatings are uniform and of high quality.

Impact on Various Industries

Surface engineering’s effects are felt in many areas, like cars, defense, and gadgets. Each field has seen big gains. For instance, cars now use laser treatments to burn less fuel and emit less pollution. The defense world gets stronger, more durable coatings. And gadgets last longer thanks to these new methods.

| Industry | Technique | Benefits |

|---|---|---|

| Automotive | Laser Treatment | Improved fuel efficiency |

| Defense | Thermal Spraying | Enhanced durability |

| Consumer Electronics | Atomic Layer Deposition | Increased longevity |

New surface engineering methods are key to creating tomorrow’s materials. They’re vital for many industries.

Material Properties and Their Importance

Understanding material properties is key for successful surface engineering. Aspects like mechanical properties, corrosion resistance, and durability are crucial. They affect how well materials perform in different settings.

Each property has its own role in determining material suitability. Thorough evaluations are needed to ensure materials meet performance standards.

Understanding Mechanical Properties

Mechanical properties show how materials react under stress. Important factors include:

- Tensile Strength: The ability to withstand pulling forces.

- Hardness: Resistance to deformation or scratching.

- Elasticity: The ability to return to original shape after stress is removed.

These properties affect material functionality and longevity. Evaluating them helps prevent failures and boosts material reliability.

Corrosion Resistance and Durability

Corrosion resistance is about a material’s ability to resist environmental damage. Materials with high corrosion resistance last longer, especially in harsh conditions. This is linked to material durability, covering physical and chemical endurance over time.

Choosing materials with good corrosion resistance boosts reliability. It also cuts down on maintenance costs, improving productivity in many industries.

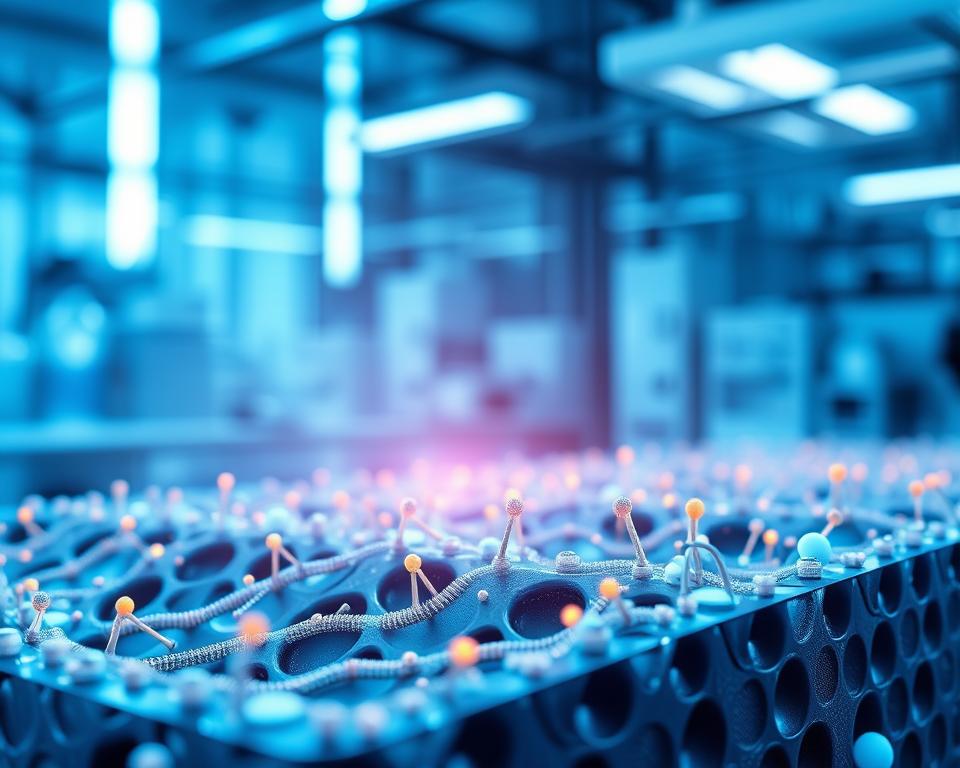

Advanced Materials Used in Surface Engineering

Advanced materials are key in surface engineering. They improve performance and function in many areas. Nano-coatings, high-performance alloys, and biomaterials have special properties for different needs.

Nano-coatings and Their Applications

Nano-coatings offer a thin layer of protection. They make things last longer by fighting off the environment. They’re used in cars and electronics to keep products looking and working better.

Research shows nano-coatings cut down on friction and boost resistance to corrosion. They also make things look better. This makes them crucial in today’s manufacturing.

High-Performance Alloys

High-performance alloys can handle extreme conditions. They’re vital in aerospace, chemical processing, and energy. Their strength and lightness help make better, more reliable structures.

New alloys are even better at resisting wear and tear. This means safer, longer-lasting products in important areas.

Biomaterials in Medicine and Electronics

Biomaterials are changing medicine and electronics. They help healing and make devices work better. In medicine, they’re used in implants and drug delivery systems.

In electronics, they help make things more eco-friendly. Biomaterials are biodegradable, reducing harm to the environment. They show a big push for health and the planet.

Materials Engineering: Challenges and Solutions

Materials engineering faces many challenges that need new solutions. Issues like managing costs, being sustainable, and materials degrading over time are big problems. These materials engineering challenges affect industries that use advanced materials a lot.

One key way to solve these problems is to find solutions in materials engineering that are both effective and green. Recycling, making manufacturing better, and creating stronger materials are important steps. Also, focusing on sustainability meets industry needs and what society wants.

The future of materials engineering looks bright with new research and ideas. Working together, universities, industries, and governments are making materials last longer and harm the environment less. By using insights from Materials Science and Engineering Reports, we can guide new materials that meet today’s needs.

| Challenge | Details | Solutions |

|---|---|---|

| Cost Management | Balancing the cost of raw materials and manufacturing | Enhanced sourcing strategies, bulk purchasing |

| Sustainability | Need for eco-friendly materials | Development of biodegradable and recyclable materials |

| Material Degradation | Wear and tear over time | Improving material properties and protective coatings |

Nanomaterials: The Future of Surface Engineering

The field of nanomaterials is growing fast and offers new chances for surface engineering. These materials have special properties. They make things stronger and lighter, perfect for many uses.

Enhancements in Strength and Weight

Nanomaterials are changing how things work in fields like aerospace and cars. They help make things stronger without adding much weight. This is key for better fuel use and performance.

Studies in Nano Letters show how nanomaterials boost material abilities.

Some common nanomaterials are:

- Metallic nanoparticles

- Carbon-based nanomaterials

- Polymeric nanoparticles

These materials make things stronger and lighter. This improves how things work and makes them more eco-friendly. The study of nanomaterials is opening up new ways to create materials, leading to many new ideas.

Material Design Innovations in Surface Engineering

Recent advancements in material design have changed the game in surface engineering. These changes improve material performance and open up new uses. Tailoring surface properties is key, leading to the creation of top-notch materials.

Tailoring Surface Properties

Tailoring surface properties means changing a material to fit its use. Coating, texturing, and chemical changes can make materials hydrophobic or increase friction. These steps help make materials that work well and save energy, like in cars or planes.

At MIT, researchers have made tools to predict surface properties. This makes research more thorough and easier to understand. For more, check out this article on predicting surface properties.

Smart Materials and Their Functions

Smart materials are a big deal in material design. They change their properties based on temperature, pressure, or electric fields. This makes them useful in robotics, healthcare, and construction.

Adding smart materials to surface engineering brings new functions. Think self-healing coatings and adaptive insulation. The future looks bright for smart materials in engineering.

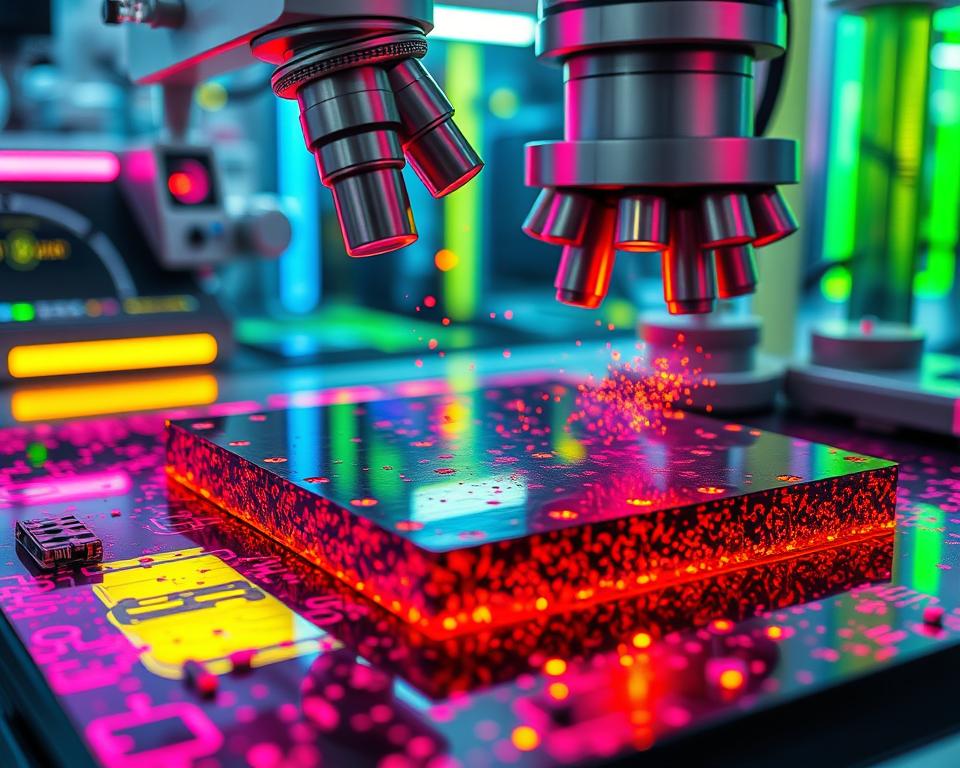

Impact of Surface Engineering on Semiconductor Materials

Surface engineering in semiconductors is key to better device performance and reliability. It enhances electronic properties and aids in thermal management. This is crucial for high-performance applications.

Surface topology greatly affects semiconductor materials. Fine-tuning the surface structure boosts charge carrier mobility. This is vital for faster transistor switching. Techniques like atomic layer deposition and chemical vapor deposition are used to achieve these modifications.

Research shows that optimized surface engineering can greatly improve product yield and lifespan. The use of nanostructured materials leads to more efficient and functional devices. The industry is constantly exploring these advancements, showing the growing importance of surface engineering in semiconductors. For more information, check out studies on surface engineering methods.

As the semiconductor industry grows, the role of surface engineering becomes more apparent. It is essential for innovation and staying competitive. Further research will likely bring more improvements in semiconductor materials and applications.

Material Science: Research Trends and Directions

Recent materials science research trends show a big move towards green and eco-friendly methods. Scientists are working on making materials that work well but also don’t harm the planet. They’re looking into materials that can break down naturally and using recycled stuff in making new products.

Computational materials science is also a big deal. New tech like advanced algorithms and machine learning helps predict how materials will act. This makes designing materials faster and more accurate, helping find the best materials for different uses.

Another trend is teaming up with experts from other fields. This mix of knowledge leads to new discoveries. It helps solve big problems in areas like tech, energy, and health.

| Research Focus | Description | Impact |

|---|---|---|

| Sustainable Materials | Development of eco-friendly materials with reduced environmental footprints | Promotes sustainability in manufacturing and product lifecycle |

| Recycling Practices | Innovative methods for reusing materials in new products | Decreases waste and enhances resource efficiency |

| Computational Materials Science | Utilization of digital tools to simulate material properties and behaviors | Accelerates material discovery and innovation through predictive modeling |

| Cross-disciplinary Collaborations | Partnerships between materials science and other disciplines | Facilitates breakthroughs and solves complex problems across industries |

These materials science research trends are shaping the future of the field. They help make materials science more green and innovative. Keeping up with these trends helps everyone in the field move forward together.

Conclusion

Surface engineering has become key in driving tech progress in many fields. This article showed how new methods and materials are changing old ways. They make things stronger, last longer, and work better.

The growth in material science is huge. It’s not just about new stuff. It’s about opening doors to more research and big discoveries. Surface engineering is leading the way in making new things possible.

Knowing how important surface engineering is, industries can use it to solve big problems. By always finding new materials, we’ll keep learning more about this exciting field. This will help us tackle today’s challenges in new ways.

Read more: Neuroscience of the Mind: Unlocking Human Potential

FAQ

What is material science?

Material science studies the properties and uses of materials like metals, polymers, and ceramics. It looks at how the atomic structure affects these properties. It also explores how to engineer materials for specific uses.

How does surface engineering enhance material properties?

Surface engineering changes a material’s surface to improve its wear, corrosion, and looks. Coatings, plating, and chemical treatments can greatly boost a material’s performance and life.

What are advanced materials?

Advanced materials are new and better than traditional ones. They include high-performance alloys, composites, and nanomaterials. These are made for high-tech uses.

What role do nanomaterials play in material science?

Nanomaterials have special properties because of their small size. They help in fields like electronics, biotechnology, and energy. Their strength and lightness make them great for aerospace and cars.

What are some common applications of surface engineering?

Surface engineering is used in many fields. In cars, it makes coatings wear-resistant. In electronics, it improves conductivity. In medical devices, it ensures biocompatibility. It boosts performance, durability, and looks.

What challenges does materials engineering face?

Materials engineering deals with issues like material wear, sustainability, and cost. Researchers are working on new solutions. They aim to improve materials while considering the future.

Can biomaterials be used in semiconductor applications?

Biomaterials are mainly used in medicine. But, their unique properties are being explored for semiconductors. This could improve electronic devices’ functionality and performance.

What is the future of material design in surface engineering?

The future of material design will focus on tailoring materials for specific needs. It will include smart materials and sustainable practices. This aims to reduce environmental impact.

How does material science contribute to technology advancements?

Material science is key to technology progress. It helps develop new materials, coatings, and methods. These improvements enhance product performance and reliability in fields like aerospace, automotive, and electronics.

What are the latest trends in materials science research?

Current research focuses on sustainable materials, recycling, and computational science. These trends aim to create innovative solutions. They meet the needs of future industries.